Exhaust Gas Flap Variants

Protect ship's engine & the exhaust system

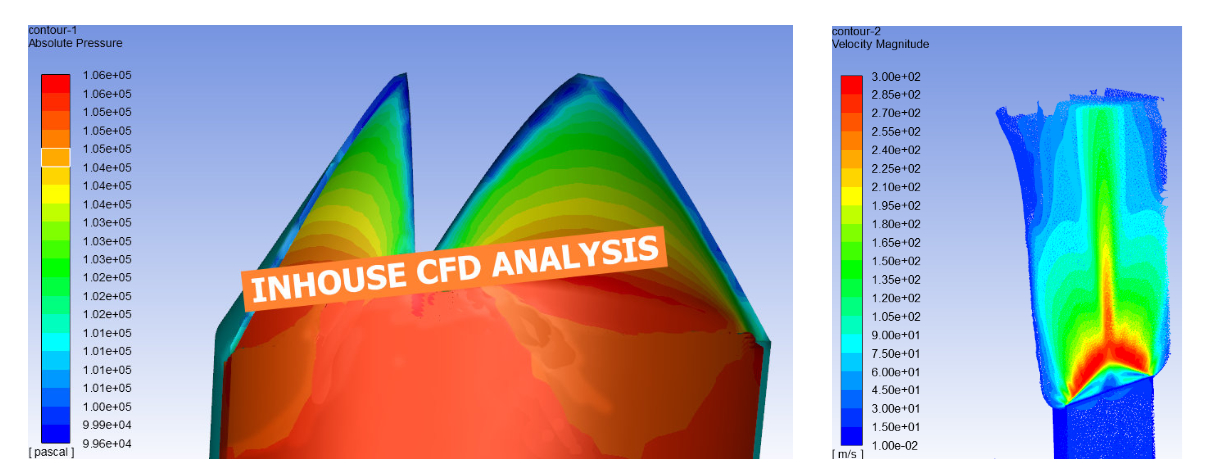

SB Broneske develops different and customised solutions for the funnel top. Considering results of inhouse 3D printing, FEM (Finite Element Method) analysis for vibration, flow or structure, we develop the best solution for the customers. We expanded our portfolio with adapted CFD (Computational Fluid Dynamics) simulations. The CFD and FEM analysis gives our experts the possibility to provide our customers with the best possible support and high quality results.

Our exhaust gas flaps are very relyable and in service over the last 20 years. They prevent the rain or splash from getting into the exhaust pipe system. Exhaust gas flaps are used to cover the vertical open ends of the exhaust pipe system. The special exhaust gas flap protects the engine and the exhaust pipe system against corrosive influences of rain and snow. Our exhaust gas flaps adjust to the operating status of the engine: They open or close while the engine starts or turns down.

The exhaust gas flaps are available from DN32 to DN3500 (stainless steel) and from DN100 to DN500 (mild steel). SB Broneske is also able to manufacture customized exhaust gas flaps. Additional sizes and materials are available on request.

Inhouse CFD and FEM analysis of the exhaust gas flow at the funnel top

CFD and FEM simulations enable us to respond even more specifically to customer requirements and exploit optimisation potential. The CFD and FEM analysis enables us to identify and exploit potential for improvement in early development phases. The analysis supports our engineers in the development and daily work. The use of these tools gives us the possibility to provide you with the best possible support and high quality results.

Please contact our experts for detailled information.

Session cookie

Session cookie